RECENT POSTS

Share:

- April 2, 2024

Table of Contents

CNC machines or numerically controlled machine tools are used to create objects by computer control. With this technology, a single operator can turn out a large number of parts or products.

The operation can be performed by feeding the program on the machine, which is controlled by a computer. It is important to understand CNC machining parts. The only two subjects that the machine operates on are CAD and CAM. The following are important CNC machining parts.

Headstock The Main CNC Machining Part

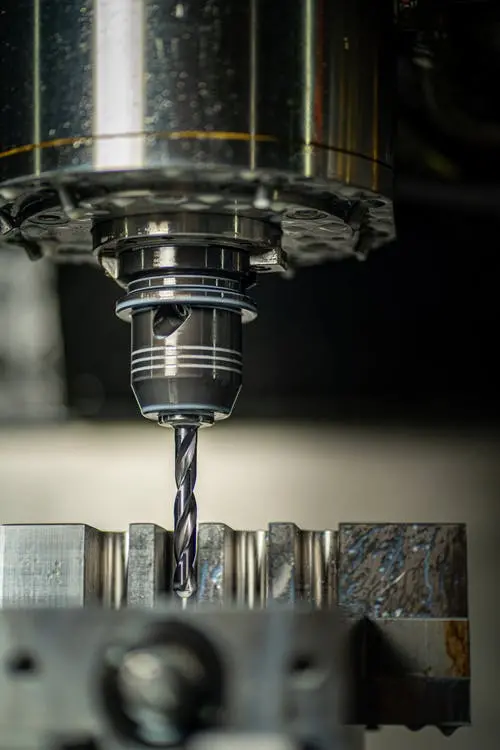

CNC machines are very important in the industry of engineering, construction, and fabrication. The Headstock is the main CNC machining part. It is used for the main motor to drive the main spindle. On the other end of the main spindle, there is a collet that holds the cutting tool. The cutting tool is attached to a tool post. The tool post is held in a vise that is clamped to the tailstock.

Tailstock

A threader holds the part while a second person threads a bolt, nut, or another fastener into it. The tailstock has a built-in vise that holds the workpiece firmly while the first person threads the fastener into the workpiece. This feature alone makes the tailstock worth its weight in gold. The live center and dead center are the two most popular styles of center points used in a lathe tailstock. The tailstock is one of the most important CNC machining parts.

Footswitch Or Pedal

It works in the same way as a tailstock quill. The “Pedal-Role” is the CNC machine’s main “ruling element.” It determines the size and shape of your parts. The “Pedal role” is the most important element of your project. It affects the project’s profitability. The pedal is also used to open and close the chuck when trying to grasp the component.

Bed

The bed is the most hardened CNC machining part. Because the turret travels over it, the structure of the bed can be different depending on the type of machine. The bed is a large horizontal structure that is used to support other parts of a lathe, e.g., tailstock and Headstock. Most of the lathes have a bed, except woodworking lathes.

Footswitch Or Pedal

It works in the same way as a tailstock quill. The “Pedal-Role” is the CNC machine’s main “ruling element.” It determines the size and shape of your parts. The “Pedal role” is the most important element of your project. It affects the project’s profitability. The pedal is also used to open and close the chuck when trying to grasp the component.

Control Panel

The control panel is another main CNC machining part. Mostly used to set or feed the program for the operation we perform on the workpiece. The CNC machine control panel has some very important functions when it comes to using a CNC machine. It keeps the machine calibrated, which means it maintains its cutting accuracy. The control panel is called the brain of a CNC machine.

Tool Turret

The turret of a CNC machine, which is also called a spindle, is a rotary head. It is used in the manufacturing process of a variety of products such as; furniture, jewelry, medical equipment, and others. It is used for component machining. Tool turrets vary in different shapes and the number of tools that can be mounted on them.

Using a CNC machine can cut your product, making time in half! A CNC router can slice designs into almost any material, including wood, plastic, fiberglass, and even tin. You can make almost any part using a CNC router. Even things you’ve never thought possible These are the CNC machining parts. For more blogs, keep visiting our website.

0