RECENT POSTS

Share:

- November 10, 2024

Table of Contents

When you take a look at the abrasive belt market, it becomes crystal clear that there is no lack of products. This, however, does not mean that you can buy any product and have it done the job without fail. You might quickly discover that there are some products out there that will not work as well as others. To avoid this, we will give you all the details and information about the top 3 abrasives belts to help you make an easy decision.

Abrasives belts: Ceramic grain sanding belt

Ceramic grain sanding belts are made from a material that is similar to ceramic glass. It’s typically used for grinding and polishing metal, but can also be used as a very aggressive sanding belt. The material is harder than steel, which means it lasts a lot longer than other kinds of abrasives. These belts are available in different grits, so you can choose the one that best suits your needs.

Ceramic grain sanding belts come in two basic types: loose and continuous loops. A continuous loop belt has a fabric backing with no gaps in between the grains of abrasive material. This type is easier to use because you don’t need to apply pressure to get good results. Loose grain belts have spaces between the grains of abrasive material, so you have to apply pressure with each pass through the wood surface to remove the material effectively.

Ceramic grain sanding belts come in two basic types: loose and continuous loops. A continuous loop belt has a fabric backing with no gaps in between the grains of abrasive material. This type is easier to use because you don’t need to apply pressure to get good results. Loose grain belts have spaces between the grains of abrasive material, so you have to apply pressure with each pass through the wood surface to remove the material effectively.

Ceramic grain sanding belts can be conducted on any kind of wood species or finish, including oil finishes and lacquers. They’re especially effective when removing deep scratches from hardwoods like oak or cherry, where other methods might damage the wood too much for refinishing or refinishing would be too time-consuming or expensive for your budget.

Abrasives belts: Zirconia grain sanding belt WX820

If you’re serious about getting a clean, smooth finish on metal, wood, or composite materials, then you need the right abrasive belt. When it comes to finding the right abrasive belt that lasts, zirconia grain sanding belts are the way to go.

Zirconia grain sanding belt WX820 is a popular abrasive material for sanding belts because of its strength and durability. The zirconia grains stay sharp, making them more effective than aluminum oxide sanding belts. Zirconia grain also has a heat resistance that makes it great for heavy-duty jobs where there’s a lot of friction and friction-produced heat. For example, when working with steel and stainless-steel surfaces, you’ll want to use an abrasive belt made from zirconia grit.

When you’re selecting your sanding belt grit size, keep in mind these general guidelines: Use a coarser grit size for grinding or stock removal and a finer grit for blending or finishing. Using the same grit size all the way through will create rough, patchy spots on your surface that will be noticeable in your final product. For example, if you’re working on something like an airplane wing structure where maximum strength is critical, then you’ll want to use a zirconia material.

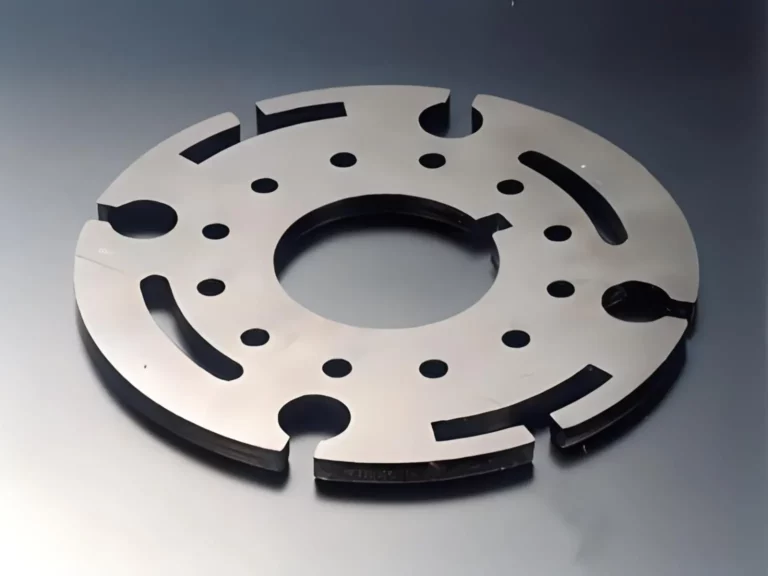

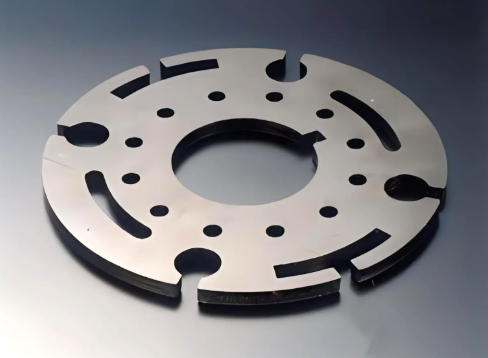

Abrasives belts: Zirconia grain sanding belt PZ533+

The Zirconia grain sanding belt PZ533+ is a ceramic grain sanding belt. It is a very high-performance abrasive material. The zirconia grain abrasive belt has great cutting performance, which is 2 times that of aluminum oxide abrasive belts. Zirconia grain sanding belts are used for grinding on metals, steel, stainless steel, etc.

PZ533+ zirconia grain sanding belts are made of Y-weight backing and resin over resin bond. The Y-wt backing provides a more rigid backing, which performs well when grinding with high pressure. Resin over resin bond is a high-strength bonding agent. It means the zirconia grit is bonded twice with synthetic resin. This bond design allows the ceramic grain to be well attached to the backing, which enables the belt to run at a higher speed.

Conclusion

Abrasive belts have a lot of uses in the garage, workshop, warehouse, etc. They’re available in a variety of different forms and work well across many surfaces. There are huge options to choose from, so it’s worthwhile to be informed when selecting your abrasive belt. We hope that this guide has helped you do that and choose the best one for you and that you enjoy your new abrasive belt!

Now it’s easy to buy and also easy to find. Ruiyan is one of the largest abrasive belt manufacturers in China with more than 26 years of experience in abrasive belts. Our products are highly recognized and trusted by our customers, including the automotive industry, engineering industry, and construction industry. We have our testing equipment and professional technical personnel to control the quality of production at every step. Good Luck!

0