Industrial PC – The Future of Automation and Control

Home » Industrial PC – The Future of Automation and Control

RECENT POSTS

Share:

- September 12, 2024

Table of Contents

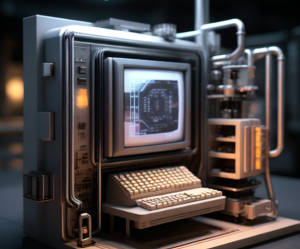

The industrial PC is increasingly becoming the preferred choice for automation and control systems across various industries. With their advanced processing capabilities, reliable hardware components, and user-friendly software interfaces, industrial PCs provide a range of benefits that traditional automation systems cannot match. In this article, we will explore the role of industrial PCs in modern industrial automation and control systems, examine their advantages and disadvantages, and consider the future trends in this rapidly developing field.

Roles and Benefits of Industrial PCs in Automation Systems

Industrial PCs are ruggedized computers designed specifically for industrial automation applications. They provide a range of features that make them suitable for a wide range of industrial processes, including data logging, process control, Batch processing, monitoring, HMI (human-machine interface), and many other functions and tasks. The main benefits of using industrial PCs include:

Processing Power: Industrial PCs offer high-performance processors that enable them to handle multiple tasks simultaneously with high efficiency. This makes them suitable for complex automation applications that require real-time processing.

Flexibility: Industrial PCs provide a range of connectivity options, including Ethernet, USB, and serial interfaces, enabling them to integrate easily with existing systems and legacy equipment.

User-Friendly Interface: Industrial PCs often come with user-friendly software interfaces that simplify programming and system configuration, making them suitable for non-technical users.

Upgradeability: Industrial PCs allow for Convenient hardware and software upgrades that help businesses stay up-to-date with the latest technological advancements.

Disadvantages of Using Industrial PCs for Automation Systems

Despite the many benefits of using industrial PCs for automation systems, some disadvantages need to be considered. One of the main disadvantages is the cost associated with using industrial PCs, which can be significantly higher than traditional automation systems. Additionally, industrial PCs may not be as rugged as traditional automation systems in some applications, which can lead to increased maintenance requirements.

Future Trends in Industrial PC Automation Systems

The future of industrial PC automation systems looks promising, with several trends expected to shape the industry in the coming years. One trend is the increasing use of edge computing, which involves performing data processing and analysis closer to the source of data generation, thereby reducing the need for data transmission over long distances. This will enable industrial PCs to handle more complex automation applications with greater efficiency and speed. Another trend is the increasing use of AI and machine learning algorithms in industrial automation systems, which will enable industrial PCs to identify patterns and trends in data more efficiently and make more accurate forecasts and decisions.

In conclusion, industrial PCs have become an essential component of modern industrial automation and control systems. With their advanced processing capabilities, reliable hardware components, and user-friendly software interfaces, they provide a range of benefits that cannot be matched by traditional automation systems. Although there are some disadvantages to using industrial PCs for automation systems, the increasing use of edge computing and AI algorithms is expected to shape the industry in the coming years and provide new opportunities for innovation and growth.

0