SMT Feeder: Essential Component in Surface Mount Technology

Home » SMT Feeder: Essential Component in Surface Mount Technology

RECENT POSTS

Share:

- November 23, 2024

Table of Contents

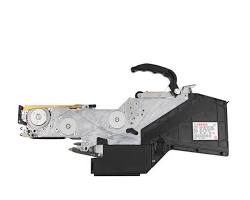

In Surface Mount Technology (SMT), the SMT feeder plays a pivotal role in ensuring the smooth and efficient operation of pick-and-place machines. It is a vital component responsible for supplying components to the machine for precise placement on printed circuit boards (PCBs). With advancements in technology, the design and functionality of SMT feeders have evolved to meet the increasing demand for speed, accuracy, and flexibility in electronics manufacturing.

The Role of SMT Feeder

The primary function of an SMT feeder is to supply components to the pick-and-place machine in an organized and timely manner. By presenting components in a specific orientation, the feeder ensures the robotic arms can easily pick them up and place them onto the PCB. This process reduces downtime and enhances overall production efficiency.

Moreover, an SMT feeder minimizes manual handling, reducing the chances of component damage or misplacement. Feeder systems are designed to handle a variety of component sizes and shapes, from tiny resistors to larger integrated circuits, making them indispensable in modern electronics assembly.

Common Types of SMT Feeders

Several types of SMT feeders are available to cater to different production needs. Each type has unique features suited for specific components and machine configurations. Below are the most common types:

1. Tape Feeder

The tape feeder is the most widely used type in SMT systems. Components are packaged in a continuous tape with pockets, and the feeder advances the tape to present each component to the pick-and-place machine. This type is ideal for small, surface-mounted components like resistors, capacitors, and diodes.

2. Tray Feeder

Tray feeders are designed for larger or more delicate components typically packaged in trays. These feeders are commonly used for integrated circuits (ICs) and other components that require careful handling. The machine retrieves components from the tray, ensuring accurate placement without damage.

3. Stick Feeder

Stick feeders are used for components supplied in tube or stick packaging. They are often employed for handling components like connectors or ICs with specific orientation requirements. These feeders ensure continuous supply while maintaining component alignment.

4. Bulk Feeder

Bulk feeders are used for high-volume production and are suitable for components supplied in bulk, such as LEDs or screws. These feeders rely on vibratory or centrifugal systems to sort and align components for pick-up.

5. Intelligent Feeder

Intelligent feeders are equipped with sensors and software to monitor and control feeding processes. They can detect errors, track component usage, and optimize feeding rates, making them ideal for high-precision and automated production environments.

Importance of Choosing the Right SMT Feeder

The choice of an SMT feeder can significantly impact production efficiency, accuracy, and quality. Selecting the right feeder type based on the component size, shape, and packaging ensures smooth operation and minimizes errors. Additionally, advanced feeders with intelligent features enhance automation and reduce manual intervention, further improving productivity.

Conclusion

The SMT feeder is a critical component in the SMT assembly process, ensuring seamless supply and accurate placement of components. By understanding the different types of feeders and their applications, manufacturers can optimize their production lines for better efficiency and quality. As technology continues to advance, SMT feeders will play an increasingly vital role in meeting the demands of modern electronics manufacturing.

0